Create a product

PRODUCT

Terblum Dysproslum Iron Megnetostrictive Material

Terbium dysprosium iron (TbDyFe) Alloy rare earth giant magnetostrictive material Terfenol-DIntroduction

Terbium-dysprosium-iron (TbDyFe) alloy is a new type of rare earth giant magnetostrictive material, and its magnetostrictive strain (magnetostrictive coefficient) at room temperature is unmatched by any previous field-induced stretching material. It is dozens of times larger than the strain of traditional nickel-cobalt (Ni-Co) and other magnetostrictive alloys, and more than five times that of electrostrictive materials. It can efficiently convert electrical energy into mechanical energy and transmit huge energy. at 10-5~ 10-6In a very short time of seconds, a hysteresis-free response matching the static and dynamic characteristics of the magnetic field is formed precisely and stably. Its response is stable, the speed is agile, so that terbium dysprosium iron alloy as a driving element of the mechanical system reaction lag time is significantly reduced, which is also terbium dysprosium iron alloy element in the alternating magnetic field in the rapid expansion and contraction strain response of the important characteristics, so that it in the industrial science and technology development as the implementation of components, control components, sensitive components have been more and more widely used.

One of the achievements in the application of rare earth giant magnetostrictive materials in the field of acoustics is the flat panel speaker technology. Flat panel speakers (Flat panel technology) have excellent frequency response characteristics and sound quality, can produce a 360-degree sound field, almost across any plane, opening up the possibility of designing various new speakers.

The use of rare earth giant magnetostrictive material elements for micro-displacement mechanisms can control complex displacement movements quickly, accurately and stably. Accurate joint control of robots; Precision displacement control of machine tool components; Servo tool rest control of molding machine tools; Compensation control of mechanism transmission error and tool wear; Power contact control of switches and relays in power distribution system; In the control of fine focusing of laser mirror, telescope and electron microscope, the structure can be significantly optimized, the performance can be improved, the efficiency can be improved and the loss can be reduced.

Random control is carried out in linear motors, servo valves, powerful hydraulic pumps, precision infusion pumps (medical), high-speed valves, fuel injection systems (automobile engines) and other devices driven by rare earth magnetostrictive materials, effectively improving the degree of automation, Simplify the hydraulic control system, achieve high efficiency, energy saving, safe and reliable.

The vibration of the mechanical system can be effectively controlled by the instant response characteristics of the terbium dysprosium iron alloy element, and the purpose of vibration elimination and noise reduction can be achieved. On the contrary, the controllable characteristics of rare earth magnetostrictive material elements are used to improve the vibration process (polishing, vibration cutting), and improve product quality and production efficiency.

The above are some examples of the application of rare earth giant magnetostrictive materials, but they are by no means the apex of the application. More applications of rare earth giant magnetostrictive materials are being developed, and it is believed that it has broad application prospects and far-reaching influence in the development of new products in all walks of life.

Hunan Chuangyi Electronic Technology Co., Ltd.Can provide terbium-dysprosium iron (TbDyFe) alloy specifications: cylindrical, diameter 2.0~50mm, length ≤ 200mm

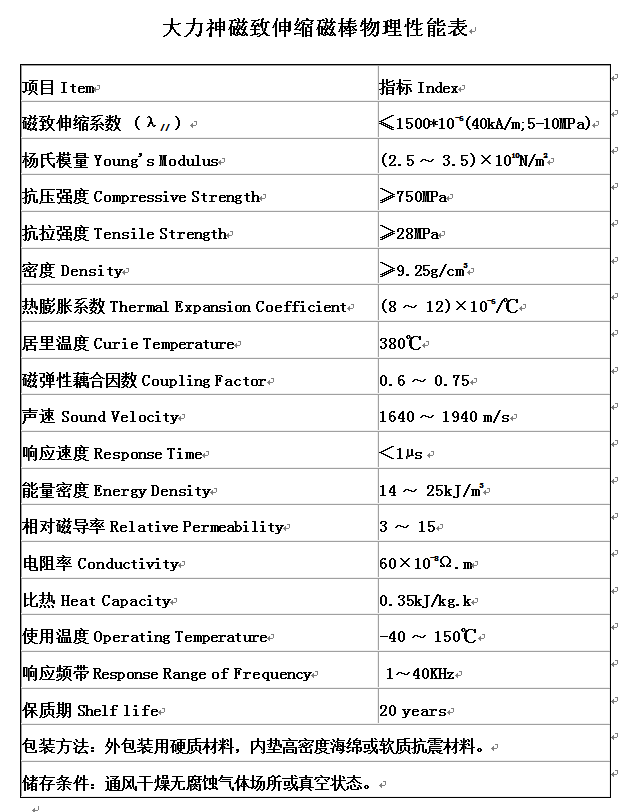

Brand: Hercules magnetostrictive magnetic rod

Supply capacity: long-term and stable mass production capacity, monthly output can reach 80~120kg

Performance and advantages: stable performance, high magnetostrictive conversion efficiency, large expansion rate and output energy, instant response without lag, high strength and not easy to break, wide range and beautiful tone when making vibration sound.

Product packaging: vacuum sealed packaging

Product use: production of new vibration sound, micro-displacement controller, ultrasonic transmitter devices, etc.

in stock specifications: diameter 30mm

toTb-Dy-FeThe giant magnetostrictive material is a new type of functional material gradually developed from the 1970 s after piezoelectric ceramics and magnetostrictive materials. It has the function of converting electromagnetic energy and mechanical energy, and is a heavy energy and information conversion energy material, especially an important material for sonar transducers. Due to its excellent magnetostrictive properties, giant magnetostrictive materials have aroused great interest as soon as they appear, and they play an increasingly important role in the national economy and industrial production. giant magnetostrictive materialTb-Dy-Fe. Has a series of excellent performance:large magnetostrictive strain, magnetostrictive strainthan pureNiBig50times, morePZTLarge material5-25Times:The magnetostrictive strain produces a large thrust with a diameter of about10mmofTb-Dy-FeThe magnetostriction of the bar produces approximately200kgthe thrust:The energy density is high, and its energy density is higherNibase alloy large400~800times, morePZTBig14~30times; energy conversion efficiency(Expresses in terms of electromechanical coefficient)Up70%, andNibase alloy only16%.PZTMaterials only40-60%:its1HThe curve is linear, the elastic modulus changes with the magnetic field, can be adjusted;10-6seconds; good frequency characteristics, can be in low frequency(Dozens1000Hertz)Working under, working frequency bandwidth; can be in low field(Tens to hundreds of Osters)work under; low working voltage, can be in a few volts100Volt voltage, can be driven by batteries, andPZTThe electric polarization voltage2kV/mm Above, there is a danger of electrical breakdown; good stability, high reliability, its magnetostrictive performance does not change over time, no fatigue, no overheating failure problems. In addition,PZTCompared with ceramics, giant magnetostrictive materials also have an irreplaceable position in low-field high-power sensors. Giant magnetostrictive materials have broad application prospects in high-tech fields such as sonar underwater acoustic transducer technology, electro-acoustic transducer technology, ocean exploration and development technology, micro-displacement drive, vibration reduction and anti-vibration, noise reduction and anti-noise system, intelligent wing, robot, automation technology, fuel injection technology, valve, pump, oil wave recovery and so on.

low frequency sound source and receiver system

Sound signals are the main medium for underwater communication detection, reconnaissance and remote control. The core element of the sonar device for transmitting and receiving sound waves is generally made of piezoelectric ceramics or magnetostrictive materials, and low frequency and high power is the future development direction of the transmitting underwater acoustic transducer for sonar and underwater acoustic countermeasure. The key material for the manufacture of low-frequency high-power underwater acoustic transducer is the rare-earth giant magnetostrictive material. The development of rare earth giant magnetostrictive materials will play a key role in the development of sonar technology, underwater acoustic countermeasure technology, ocean development and detection technology.<112 >Axially oriented giant magnetostrictive materialsTerphenol-Dand<110>axial orientationTb-Dy-Fewith piezoelectric ceramicsPZTCompared to the following advantages:High output power, high working temperature, low voltage drive, small hysteresis, no aging, low response frequency, low frequency signal attenuation under water, long transmission distance, etc. This makes it possible for giant magnetostrictive materials to be first used in sonar systems.

In addition,Ultrasonic generators made of giant magnetostrictive materials have good application prospects in fishing, seabed surveying and mapping, and non-destructive testing of buildings and materials.Terphenol-DThe combination of excellent low-frequency acoustic characteristics and high-frequency characteristics of piezoelectric ceramics can produce acoustic vibration sensors with better performance, with wide frequency response and good unidirectional. The use of magnetostrictive material elastic modulus changes with the magnetic field properties, can be made with the frequency of magnetic field adjustable delay line, resonator and filter and other devices in sonar or other systems.

Ultrasonic technology and electroacoustic transducer technology

Rare earth giant magnetostrictive materials also have broad application prospects in acoustic and ultrasonic technology. For example, ultra high power ultrasonic transducers can be manufactured from this material. In the past, ultrasonic transducers were mainly made of piezoelectric ceramics.(PZT)materials to manufacture. It can only make small power(≤ 2.OkW)The ultrasonic transducer, foreign countries have used rare earth magnetostrictive materials to produce ultra-high power.(6~25kW)of the ultrasonic transducer. Ultra-high-power ultrasonic technology can produce new physical effects and new uses that low-power ultrasonic technology cannot produce. For example, it can desulfurize and regenerate waste tires, greatly increase crop production, accelerate chemical reactions in chemical processes, and have significant economic, Social and environmental benefits; electroacoustic transducers made of this material can be used for fluctuating oil production, which can increase the oil production of oil wells up20%~100%It can promote the development of the oil industry.

High energy fast micro displacement actuator

The giant magnetostrictive material not only has large magnetostrictive strain, but also has large output stress and fast response speed. Therefore, it can be used for the design of high-energy and fast micro-machinery. The micro-displacement actuator made of rare earth giant magnetostrictive material can be used for robots, Automatic control, ultra-precision machining, infrared, electron beam, laser beam scanning control, camera shutter, linear motor, intelligent wing, fuel injection system, micro pump, micro pump, valve, sensor, etc.

Other Sensor Applications

Using the characteristics of large magnetostrictive strain and fast response speed, giant magnetostrictive materials can be used to measure any physical quantities related to magnetic fields. In addition, the thin type made of this material.(Plate type)Horn, vibration force, good sound quality, high fidelity, can make floor, wall, desktop, glass window vibration and pronunciation, can be used for underwater music, underwater ballet dance horn. Noise and noise control, anti-vibration and vibration control systems can be manufactured with this material.